This article may contain references to products or services from one or more of our advertisers or partners. We may receive compensation when you click on links to those products or services. Nonetheless, our opinions are our own.

The information presented in this article is accurate to the best of our knowledge at the time of publication. However, information is subject to change, and no guarantees are made about the continued accuracy or completeness of this content after its publication date.

Apple has had a strong manufacturing presence in China for years. This is because the region has a skilled workforce, efficient production capabilities, and a well-established supply chain network. Tim Cook, the CEO of Apple, has said that China’s advantage is not only that it is cost-effective, but also that its workers have a lot of technical knowledge and the country can quickly ramp up production.

Apple has announced a $500 billion investment in American innovation, especially as global supply chains and economic priorities evolve. This move seems to be an effort to boost research and development, strengthen manufacturing in the US, and build a highly skilled workforce. This investment is a big step toward relying less on overseas production, but the transition will be difficult, especially when it comes to training workers, building supply chain infrastructure, and keeping costs down.

- Why China Has Been Apple’s Manufacturing Powerhouse

- The U.S. Investment: A Shift Toward Domestic Production?

- Challenges of Moving More Manufacturing to the U.S.

- Long-Term Implications for the Technology Industry

- Takeaways

- What’s Next for Apple?

- Frequently Asked Questions

- Why has Apple traditionally relied on China for manufacturing?

- What is Apple’s $500 billion U.S. investment focused on?

- Is Apple moving all manufacturing to the United States?

- What are the main challenges Apple faces in reshoring manufacturing to the U.S.?

- How will this affect Apple’s supply chain?

- Will Apple products become more expensive if made in the U.S.?

- How does this affect the broader technology industry?

- What role does automation play in Apple’s U.S. strategy?

- When will the effects of Apple’s investment be visible?

- Can the U.S. truly replace China as Apple’s main manufacturing base?

- Recommended Reads

Why China Has Been Apple’s Manufacturing Powerhouse

China’s dominance in large-scale manufacturing is not solely about labor costs. Instead, its robust industrial ecosystem, technical expertise, and established supplier networks make it an ideal location for companies like Apple. Unlike many other countries, China has spent decades building a system where component suppliers, assembly lines, and skilled labor are readily available in close proximity, ensuring seamless production at scale.

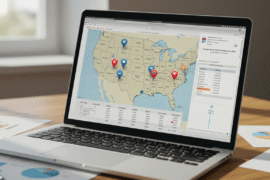

| Factors | United States | China |

|---|---|---|

| R&D Investment | Strong in innovation and technology | Moderate but rapidly growing |

| Manufacturing Scale | Developing, with a focus on automation | High, with established infrastructure |

| Workforce Training | Limited availability of specialized training | Extensive, with vocational programs |

| Supply Chain Integration | Fragmented, requiring development | Highly integrated and efficient |

| Production Costs | Higher labor and operational expenses | More cost-efficient |

Apple’s dependence on China extends beyond manufacturing alone. The country’s expertise in precision engineering and assembly-line efficiency is difficult to replicate elsewhere, making it a challenging environment to move away from.

The U.S. Investment: A Shift Toward Domestic Production?

Apple’s recent $500 billion investment initiative includes significant funding for research and development, workforce training, and infrastructure improvements within the United States. This effort aligns with broader efforts to revitalize American manufacturing, particularly in areas such as semiconductor production, automation, and sustainable energy solutions.

Some of the objectives of this investment include:

- Expanding R&D Facilities: Apple plans to strengthen its innovation hubs, focusing on advanced computing, artificial intelligence, and next-generation chip development.

- Investing in Workforce Training: Training programs and educational partnerships aim to equip workers with the technical skills needed for high-tech manufacturing roles.

- Enhancing Domestic Production: Apple is looking to increase its reliance on U.S.-based suppliers and manufacturers, particularly in semiconductor production, where domestic capabilities are currently limited.

While these efforts represent an important step forward, the success of this transition depends on long-term commitments to developing a skilled workforce and improving supply chain infrastructure.

Challenges of Moving More Manufacturing to the U.S.

Although Apple’s investment is ambitious, several obstacles must be addressed before the U.S. can compete with China’s level of efficiency and scalability.

- Workforce Shortages: The U.S. currently lacks a large pool of workers with specialized manufacturing expertise, particularly in areas such as precision assembly and supply chain logistics. Expanding vocational education and hands-on training will be essential.

- Supply Chain Development: Unlike China, the United States does not have an established network of suppliers and component manufacturers located in close proximity. Strengthening domestic supply chains will require significant investment and collaboration across industries.

- Higher Production Costs: Manufacturing in the U.S. comes with higher labor and operational costs, making it necessary to invest in automation and efficiency improvements to remain competitive.

While Apple’s investment is a step toward addressing these challenges, it remains uncertain whether the U.S. can match China’s well-oiled manufacturing ecosystem in the near future.

Voted "Best Overall Budgeting App" by Forbes and WSJ

Monarch Money helps you budget, track spending, set goals, and plan your financial future—all in one app.

Get 50% OFF your first year with code MONARCHVIP

Long-Term Implications for the Technology Industry

Apple’s move to increase U.S.-based manufacturing could set a precedent for other technology companies, encouraging broader investments in domestic production, supply chain resilience, and workforce training. However, the transition away from a China-centered manufacturing model is not likely to happen overnight.

For Apple, the challenge is not only about shifting production but also about ensuring that manufacturing capabilities in the U.S. can reach the same level of efficiency, scalability, and quality that China currently provides. Success in this area will depend on:

- The growth of automation technologies to offset higher labor costs

- Continued investment in semiconductor manufacturing to reduce dependence on overseas chip production

- Expansion of training programs and partnerships to develop a highly skilled workforce

While Apple’s investment reflects confidence in American innovation, the road ahead remains complex. The ability to successfully build a competitive manufacturing infrastructure will depend on sustained efforts from both the private and public sectors.

Takeaways

- Apple has relied on China’s skilled workforce, supply chain efficiency, and large-scale production capacity for years.

- The $500 billion U.S. investment aims to enhance domestic manufacturing but faces challenges related to workforce training, supply chain limitations, and cost efficiency.

- The success of Apple’s shift depends on long-term infrastructure development, automation advancements, and workforce expansion.

- While this investment signals a strategic move toward domestic production, China’s established manufacturing ecosystem remains difficult to replace in the near term.

Apple’s strategy reflects a broader shift in global supply chain dynamics, raising important questions about the future of manufacturing and technological innovation. Whether the U.S. can establish itself as a competitive hub for advanced manufacturing remains to be seen.

What’s Next for Apple?

Apple’s investment suggests that the company is taking concrete steps toward reducing reliance on foreign manufacturing, but the effectiveness of this strategy will become clearer over time. Will the U.S. be able to develop the workforce and supply chain necessary to support large-scale production at Apple’s level? Or will China remain the unrivaled leader in high-tech manufacturing?

The coming years will reveal whether Apple’s investment can truly transform the landscape of technology manufacturing and innovation.

Frequently Asked Questions

Why has Apple traditionally relied on China for manufacturing?

China has a mix of skilled workers, efficient production, integrated supply chains, and lower costs. Apple can quickly increase production and keep it very precise because its manufacturing ecosystem brings together suppliers, assembly plants, and trained workers in close proximity.

What is Apple’s $500 billion U.S. investment focused on?

Apple’s investment is geared toward boosting American innovation through expanded R&D facilities, workforce training programs, domestic manufacturing, and improvements in supply chain infrastructure. Key areas include artificial intelligence, chip development, and automation technologies.

Is Apple moving all manufacturing to the United States?

No. Apple is not completely shifting manufacturing out of China. Instead, the investment aims to reduce reliance on foreign production by developing stronger domestic capabilities over time. China’s established manufacturing strengths remain essential in the near term.

What are the main challenges Apple faces in reshoring manufacturing to the U.S.?

The primary challenges include:

Workforce shortages in specialized manufacturing skills

Lack of a mature supply chain ecosystem within the U.S.

Higher production costs, particularly labor and operations

How will this affect Apple’s supply chain?

If successful, Apple’s efforts could diversify its supply chain and make it more resilient to global disruptions. It may also lead to greater use of U.S.-based suppliers and reduced dependency on regions like East Asia for critical components.

Will Apple products become more expensive if made in the U.S.?

Possibly. Higher labor and operational costs in the U.S. could impact product pricing. However, Apple may offset this through increased automation, operational efficiency, and long-term supply chain savings.

How does this affect the broader technology industry?

Apple’s move may influence other tech companies to invest more in domestic production and workforce training. It could lead to a gradual shift toward localized manufacturing and supply chain resilience, especially in critical sectors like semiconductors.

What role does automation play in Apple’s U.S. strategy?

Automation is critical to making U.S.-based production cost-effective. Apple’s investment will likely support the development and integration of advanced manufacturing technologies to reduce labor dependence and increase efficiency.

When will the effects of Apple’s investment be visible?

The impact will take years to fully materialize. Workforce training, infrastructure development, and supply chain integration require long-term commitment and collaboration between the private and public sectors.

Can the U.S. truly replace China as Apple’s main manufacturing base?

Not in the short term. While the U.S. can strengthen its capabilities, China’s scale, integration, and technical labor force make it difficult to displace quickly. Apple’s strategy is more about diversification and resilience than outright replacement.

Reviewed and edited by Albert Fang.

See a typo or want to suggest an edit/revision to the content? Use the contact us form to provide feedback.

At FangWallet, we value editorial integrity and open collaboration in curating quality content for readers to enjoy. Much appreciated for the assist.

Did you like our article and find it insightful? We encourage sharing the article link with family and friends to benefit as well - better yet, sharing on social media. Thank you for the support! 🍉

Article Title: Apple’s China Focus and 0B U.S. Investment Explained

https://fangwallet.com/2025/06/21/apple-manufacturing-strategy/The FangWallet Promise

FangWallet is an editorially independent resource - founded on breaking down challenging financial concepts for anyone to understand since 2014. While we adhere to editorial integrity, note that this post may contain references to products from our partners.

The FangWallet promise is always to have your best interest in mind and be transparent and honest about the financial picture.

Become an Insider

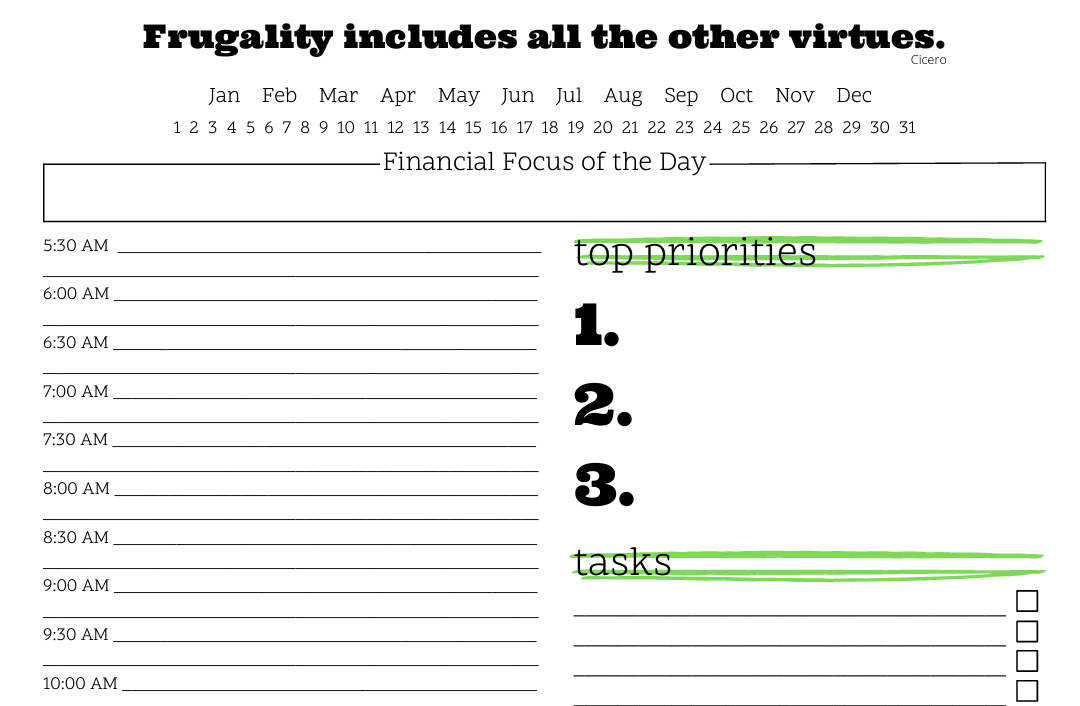

Subscribe to get a free daily budget planner printable to help get your money on track!

Make passive money the right way. No spam.

Editorial Disclaimer: The editorial content on this page is not provided by any of the companies mentioned. The opinions expressed here are the author's alone.

The content of this website is for informational purposes only and does not represent investment advice, or an offer or solicitation to buy or sell any security, investment, or product. Investors are encouraged to do their own due diligence, and, if necessary, consult professional advising before making any investment decisions. Investing involves a high degree of risk, and financial losses may occur including the potential loss of principal.

Source Citation References:

+ Inspo

There are no additional citations or references to note for this article at this time.