This article may contain references to products or services from one or more of our advertisers or partners. We may receive compensation when you click on links to those products or services. Nonetheless, our opinions are our own.

Updated by Albert Fang

Inventory is essential in organizations as it facilitates the planning of the production line. It also helps you manage your resources and provide a platform for measuring quality and productivity.

However, most businesses still use traditional ways of managing their supply. Research shows that 24% of startup companies use pen and paper to monitor their inventory. This often leads to errors in data collection and poor control over stock levels. In other words, these organizations are prone to running out-of-stock or overstocking, which wastes time and resources.

This is why 75% of supply chain management experts intend to enhance their inventory management practices. This helps them identify bottlenecks in the process, reduce wastage, and increase profits. That way, they’re able to meet customer demand more efficiently and make better use of their scarce resources at the same time.

The following is a list that’ll help you ensure the effectiveness of your inventory management strategies:

Calculate WIP Inventory

Work-in-progress or WIP inventory is the cost of goods being produced or worked on. It’s also known as finished goods inventory that has yet to be completed but not yet shipped out.

The purpose of this inventory is to track the time spent on a particular project and how much it’ll cost to complete it. It helps you manage your project schedule, costs, and deadlines.

To calculate it, you can use this formula: “COGM = Total Manufacturing Costs + Beginning WIP Inventory – Ending WIP Inventory.” This will help you identify the exact number of inventories and know how much it’ll cost to finish all your products. From there, you can figure out ways to optimize your supply chain to ensure that it drives more revenue.

Forecast Product Demand

Demand forecasting is vital in inventory management as it helps determine the amount of inventory needed and how long it’ll take to produce that inventory. With proper forecasting, you may avoid overstocking your shelves with items people want but don’t buy. You can do accurate demand forecasting with a good cloud MRP software and manage your inventory level efficiently.

For example, you’re selling a product that requires large amounts of space on your shelf and no one is buying them. Then, you could be overstocking the shelves with products that no one wants or needs. This causes unnecessary costs for you and wastes materials and time spent on unsold stock.

A forecast should include product demand history from past and current sales volume and estimated future demand from projected sales volume. That way, you can determine how much inventory is needed to meet demand at any given time without wasting resources.

Establish Proper Warehouse Management

Warehouse mismanagement is a major cause of inventory loss. For instance, you might need better planning and adequate systems that allow the accurate monitoring of the warehouse. Poor planning can also be caused by simple errors in your inventory system or by having too many items on hand. In either case, this hurts the efficiency of your business.

As such, you may improve your warehouse using technology like warehouse management systems. A study shows that 60% of these systems now have mobile capabilities, enabling real-time inventory monitoring, whereas it reduces the average order picking time by 30%. This results in less inventory loss and higher profits for your business.

Implement A Cycle Counting Program

An inventory cycle count is where you’ll take a set number of items out of your inventory and re-enter them. This aims to ensure that there are no discrepancies between what you have in the system and what you’re selling.

You can implement this using statistical sampling methods to identify inventory discrepancies and then adjust the quantity of product on hand accordingly. These include control group, hybrid, objective counting by surface area, or opportunity based. All these can help you improve your efficiency and accuracy while reducing costs associated with poor inventory management.

Embrace Lean Manufacturing

Lean manufacturing focuses on reducing waste and improving efficiency. It’s a process that aims to improve the efficiency of a company through continuous improvement.

Most companies do this by investing in innovative factory initiatives. Research shows that 10 to 12% of them receive gains in areas like labor productivity and manufacturing output. Meanwhile, 75% of manufacturers decided to use cloud technology before 2021. This proves that it’s possible to implement lean manufacturing techniques regarding inventory management. If you’re able to adopt this approach, you’ll be able to reduce inventory costs and increase profits at the same time.

Key Takeaways

Inventory management is a critical part of your business. Without it, you can’t increase sales, reduce costs, and maximize profits. Not only that, but you’re also throwing away opportunities on missed sales when you run out of stock. On the other hand, you’re wasting resources if you overstock, especially if you’re selling perishable goods.

But with proper inventory management practices, you can control costs and make more money in the long run while boosting operational efficiency. In addition, you can ensure that you meet the demands of your consumers, making them have a satisfying experience with your brand.

Reviewed and edited by Albert Fang.

See a typo or want to suggest an edit/revision to the content? Use the contact us form to provide feedback.

At FangWallet, we value editorial integrity and open collaboration in curating quality content for readers to enjoy. Much appreciated for the assist.

Did you like our article and find it insightful? We encourage sharing the article link with family and friends to benefit as well - better yet, sharing on social media. Thank you for the support! 🍉

Article Title: 5 Tips And Practices For Effective Inventory Management

https://fangwallet.com/2023/03/21/5-tips-and-practices-for-effective-inventory-management/The FangWallet Promise

FangWallet is an editorially independent resource - founded on breaking down challenging financial concepts for anyone to understand since 2014. While we adhere to editorial integrity, note that this post may contain references to products from our partners.

The FangWallet promise is always to have your best interest in mind and be transparent and honest about the financial picture.

Become an Insider

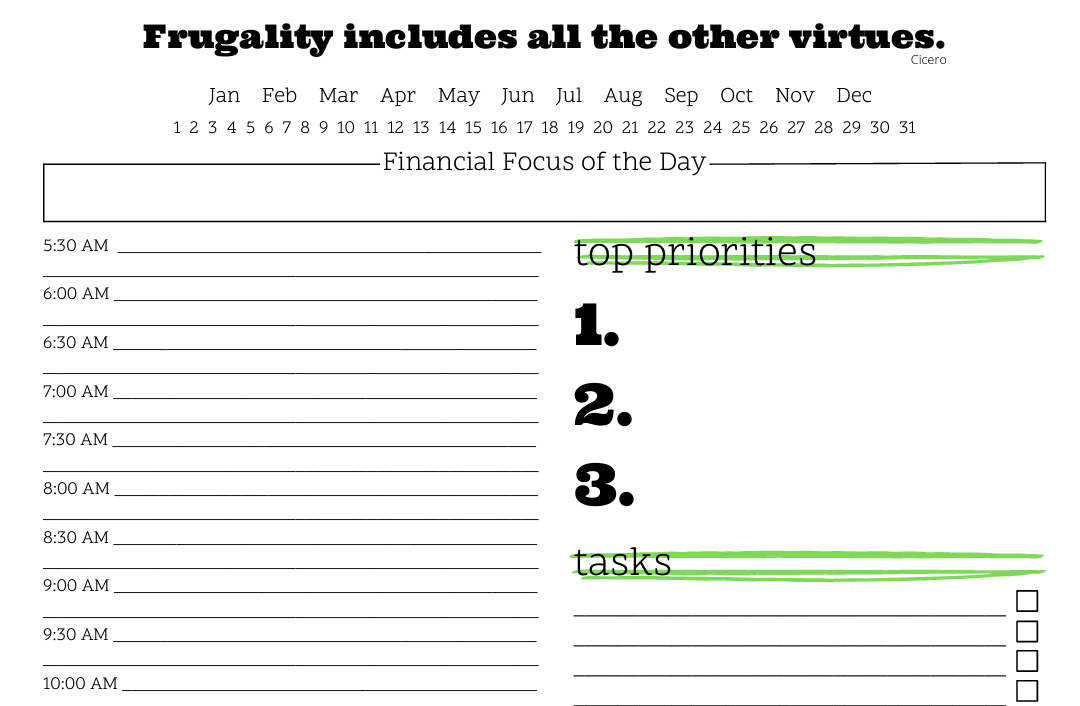

Subscribe to get a free daily budget planner printable to help get your money on track!

Make passive money the right way. No spam.

Editorial Disclaimer: The editorial content on this page is not provided by any of the companies mentioned. The opinions expressed here are the author's alone.

The content of this website is for informational purposes only and does not represent investment advice, or an offer or solicitation to buy or sell any security, investment, or product. Investors are encouraged to do their own due diligence, and, if necessary, consult professional advising before making any investment decisions. Investing involves a high degree of risk, and financial losses may occur including the potential loss of principal.

Source Citation References:

+ Inspo

![How to Hire Fintech Software Developers [Cost & Factors] fintech software engineers](https://fangwallet.com/wp-content/uploads/2025/03/fintech-software-engineers-270x180.png)