This article may contain references to products or services from one or more of our advertisers or partners. We may receive compensation when you click on links to those products or services. Nonetheless, our opinions are our own.

The information presented in this article is accurate to the best of our knowledge at the time of publication. However, information is subject to change, and no guarantees are made about the continued accuracy or completeness of this content after its publication date.

Updated by Albert Fang

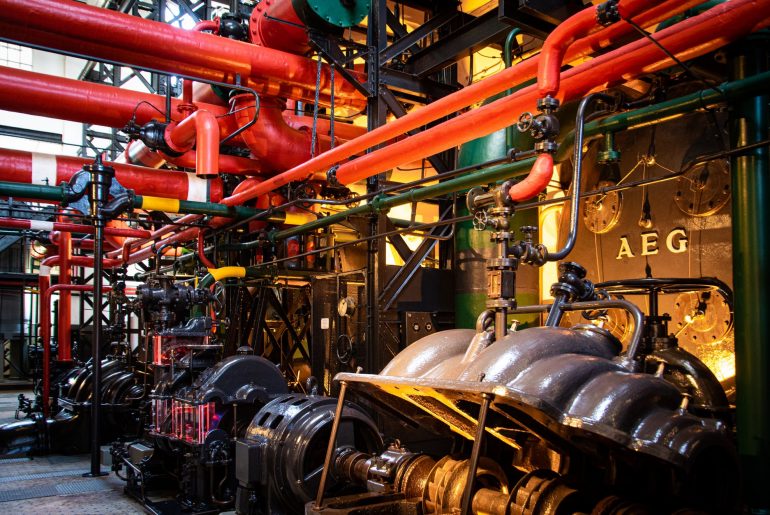

In a 2017 article, Forbes magazine stated that automation could save businesses over 4 million dollars a year. Integrating automation and artificial intelligence across various fields and sectors, especially manufacturing, has the potential to save a lot of money. At the same time, it can improve productivity, and increase efficiency.

According to a report the article refers to, three percent of all employees said they could save around two hours of work per day through automation. That means each employee can save almost 240 work hours every year. 78 percent of business leaders can save around 360 work hours every year through the same automation. Hypothetically, a company that embraces automation can save up to 4.7 million US dollars per year, no matter the industry they are in.

These are staggering numbers, and having established that, there is no doubt that automation is indeed the key to business efficiency both in terms of costs and productivity. The question is, how is it so? How does automation save money for businesses and industries? That is what we will try to find out in this article.

Reduce Packaging and Labeling Costs

A good amount of time in the manufacturing industry is spent on packaging and labeling. Automating them will bring both these processes under a single pipeline which will be more cost-efficient.

Take automated labeling systems for example. These systems can provide labeling solutions for all sorts of industries including medical, pharmaceuticals, food and beverage, consumer goods, and so on. You can use them to label products from all angles including top and bottom, front and back, horizontal wraps, etc. So there is no doubt that these systems are highly efficient.

Apart from that, automated labeling can save you money as well. A 2004 research conducted by Wright State University for a Japanese company suggests that automated labeling can lead to annual DTR savings of over $21,000, as well as reduce scrap costs by another $11,000.

Compared to the technology used in 2014, modern automated labeling systems are more advanced, often powered by artificial intelligence. Hence, today’s systems are bound to be more efficient in terms of productivity and costs.

Save Labor Costs

In China, one of the world’s manufacturing superpowers, automation plays a vital role in the production process. Whatever the type of product, you will see that the system is automated in one way or another. And all this is done to save labor costs. Here is how that works.

An automated machine that costs around $300,000 can replace 10 workers. The total yearly salary of these workers is around $70,000. On the other hand, the machine’s electricity cost is around $1,500 a year. So, although the initial investment seems high, in 10 years, you will see that the machine costs almost twice as less as the workers.

In addition to factory labor costs, you can save money on office employees as well through the implementation of system automation. This sort of automation mostly deals with online sales, office administration, and inventory management.

Ecommerce platforms use ERP software to handle online sales as well as payments. The same technology is used internally within the office to keep track of employee attendance, resource distribution, and inventory management. This allows businesses to avoid spending money on additional manpower needed to input and update all this data manually.

Reduce Additional Costs Due to Poor Quality

Between 2010 to 2015, federal agencies in the US issued more than 4000 product recalls per year on average. These products included children’s toys, automobiles, food, pharmaceuticals, consumer goods, and so on. In most cases, the reasons behind the recalls are due to issues in quality. That is something businesses can avoid with advanced automated systems.

While machines do contribute to the manufacturing of most of these products, human intervention is there as well. As a result, there is a loss of consistency. Unlike machines, humans cannot replicate the same action multiple times, no matter how skilled they are. Besides, humans can make mistakes; automated machines hardly do so.

Through automation, industries can maintain consistency. They can minimize the loss in quality, which in turn will help them avoid product recalls.

Apart from these points, automation can help businesses and industries save money in various other ways. Ultimately, it comes down to how companies use automation technology. It also depends on how creative businesses can get with them when it comes to saving money and resources.

Reviewed and edited by Albert Fang.

See a typo or want to suggest an edit/revision to the content? Use the contact us form to provide feedback.

At FangWallet, we value editorial integrity and open collaboration in curating quality content for readers to enjoy. Much appreciated for the assist.

Did you like our article and find it insightful? We encourage sharing the article link with family and friends to benefit as well - better yet, sharing on social media. Thank you for the support! 🍉

Article Title: How Automation Can Save Businesses and Industries Money

https://fangwallet.com/2021/08/06/how-automation-can-save-businesses-and-industries-money/The FangWallet Promise

FangWallet is an editorially independent resource - founded on breaking down challenging financial concepts for anyone to understand since 2014. While we adhere to editorial integrity, note that this post may contain references to products from our partners.

The FangWallet promise is always to have your best interest in mind and be transparent and honest about the financial picture.

Become an Insider

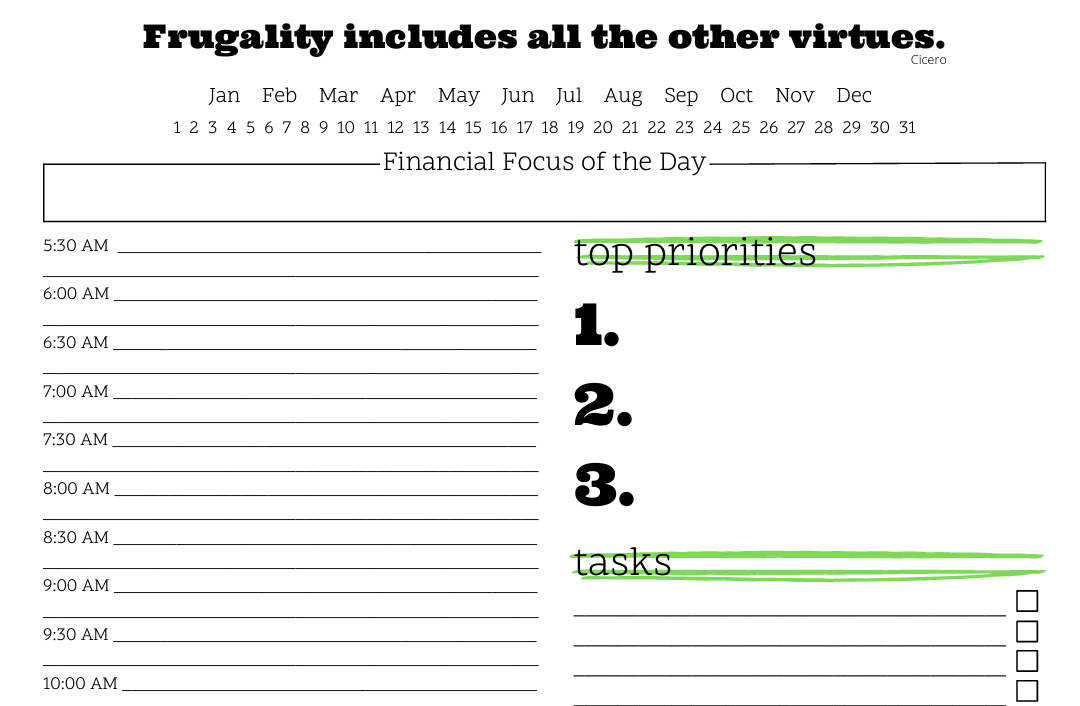

Subscribe to get a free daily budget planner printable to help get your money on track!

Make passive money the right way. No spam.

Editorial Disclaimer: The editorial content on this page is not provided by any of the companies mentioned. The opinions expressed here are the author's alone.

The content of this website is for informational purposes only and does not represent investment advice, or an offer or solicitation to buy or sell any security, investment, or product. Investors are encouraged to do their own due diligence, and, if necessary, consult professional advising before making any investment decisions. Investing involves a high degree of risk, and financial losses may occur including the potential loss of principal.

Source Citation References:

+ Inspo